Installation of the kit to consume CNG

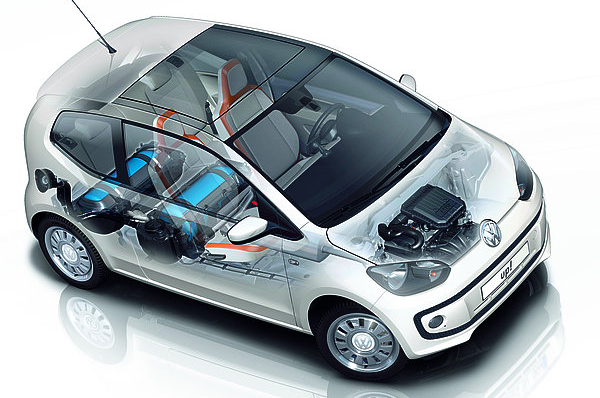

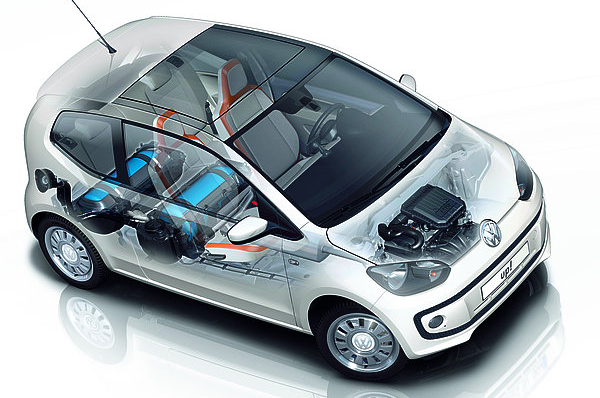

Although it is commonly called "transformation of a car to CNG" the installation in a vehicle is done maintaining the fuel system of gasoline, adding the compressed natural gas system, so that it is always possible to work alternately with one or another fuel (gasoline and compressed natural gas, for this reason they are also called "Bi-Fuel")

The installation of the entire system necessary to consume compressed natural gas as fuel in our car is simple, since the amount of components installed in the car is low, so the chances of breakdowns or malfunction are rare. < / p>

The equipment may vary according to the installation required, but in general they have the following elements common to all types: Equipment brands to use Compressed Natural Gas There are many different equipment to choose to adapt our car to consume compressed natural gas, probably the most important factor to choose the installation of one or the other equipment, is the experience of the installer workshop with the equipment A car with compressed natural gas enjoys a double autonomy because it works with compressed natural gas and always has at its disposal to use the car in gasoline mode at will

Humans have been using natural gas for thousands of years, in fact, it is believed that the Chinese already used it in 500 BC. Boil and purify water Natural gas was used to power the streetlights in 1785, and was the main source of light during the 19th century. The invention of the electric bulb in 1879 forced natural gas companies to seek other uses for the resource and, as a result, natural gas became a very popular source of energy.

Natural gas vehicles have been documented as early as the 1930s, although it is not clear exactly when or who invented them. The first Natural Gas vehicles operated with uncompressed gas and were called Gas Bag vehicles. These vehicles were used as a necessary way to combat the gasoline shortage during the First World War, and even more during World War II.

The first Natural Gas cars had a wood, or metal structure mounted on the roof and attached to the bumpers, with a huge and unmanageable balloon for a gas tank. These first vehicles attracted a lot of attention, and clearly had less than ideal aerodynamics. CNG tanks are still notoriously large, occupying approximately twice as much space as gasoline tanks for the equivalent amount of fuel. This can be discouraging, but we have come a long way and we continue to improve.

CNG Technical DataCNG Heating Power : The CNG's Heating Power is around 2063 Kcal / liter, while Gasoline is around 8005 Kcal / liter. Which explains the loss of power in carburetion engines and the increase in consumption in the injection engines.

Storage Pressure : The Storage Pressure is at 200 bar, pressure at which it is kept compressed and which is approximately the pressure a submarine supports at 2000 meters. depth

Octano Index : The Octane Index for CNG is around 130 octane.

Density : Density around 0.158 kg / liter

Storage Temperature : The storage temperature is less than 0 degrees, which together with the necessary pressure results in a large amount of energy stored in a small volume.

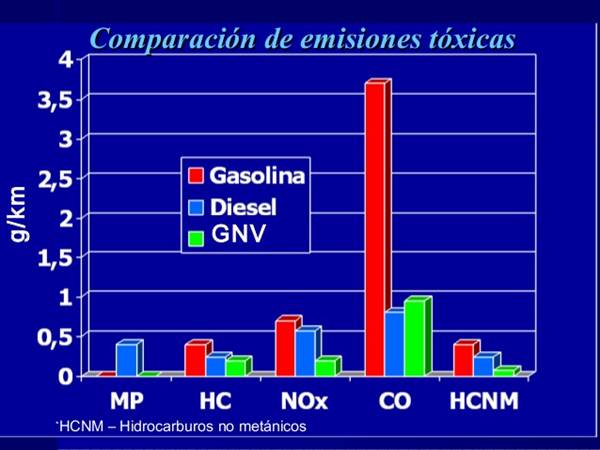

NOx particulate emissions : In tests conducted by the Argonne National Institute, dependent on the Department of Energy of the United States Government with different models of vehicles and their versions CNG, Diesel and Gasoline results showed an emission of particles that they reduced emissions of diesel models by 95%. As well as a NOx emission reduction of 49%

CO2 emissions : In the same experience it was possible to verify that CO2 emissions were reduced by 20.8% with respect to the established limit and between 17 and 34% on gasoline emissions.

Safety in the use of CNG as a fuel

The pressure elements that are integrated in the CNG vehicle are manufactured in accordance with the European standard EC-R110 and as a pressure equipment it is necessary to examine both the tank and the pipes every four years.

Both the tanks and the pipes are made of resistant materials that, in case of leakage, would evacuate the natural gas in a controlled manner

Vehicle burning is a relatively rare occurrence, but its effects can be devastating. Also against this incident are installed safety measures consisting of hot melts that in case of fire the vehicle would lead to the controlled exit of gas. These hot melts would come into action when the temperature of the fire exceeded 600 ° C

Normally the compressed natural gas installations carried out in the United States have a guarantee of 2 years, 3 years in some cases (contact the distributor for more information). This guarantee is provided by the manufacturer brand and usually covers the possible affected parts, that is, the combustion chamber, valves, cylinders, ... which will be the only thing that can be in contact with the compressed natural gas